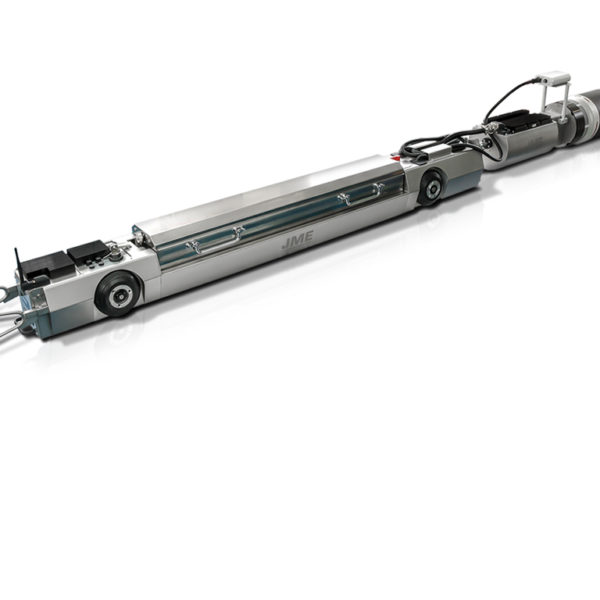

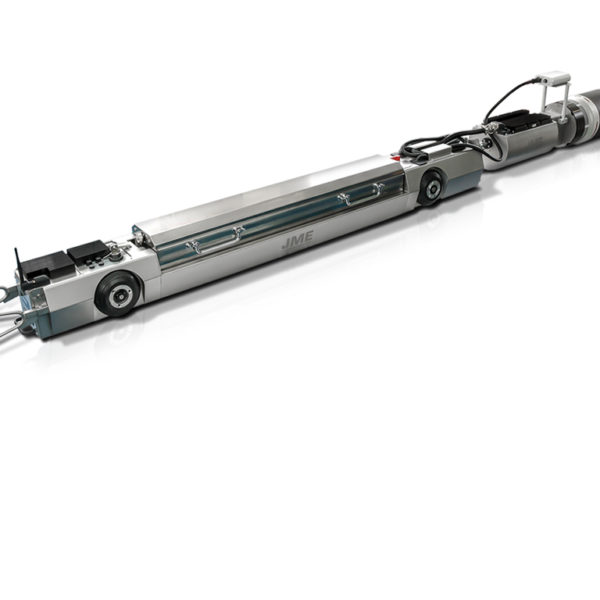

The JME MIDI 10″ Pipeline Crawler is capable of driving a wide range of X-Ray generators and gamma head / actuator units, enabling internal panoramic Single Wall Single Image (SWSI) radiography to be carried out in pipe diameters from 10″-48″.

Constructed using high grade materials to provide a good finish, superior corrosion resistance, easy maintenance and extended service life. Electronic circuitry utilising military specification components, ensuring reliability in harsh environments.

Powered by high-efficiency rechargeable sealed lead acid batteries.

Full remote control of travel, park and exposure modes from outside the pipeline using the JME ‘Magnetope’ or a low activity isotope.

Safety features include anti-runaway circuitry, and optional retrieval latching purpose built recovery vehicle and an automatic radio recovery system.

All backed by a 12 month warranty which covers all components and workmanship. (excluding radiography source).

Additional Information :

Weight (Excluding X-Ray Tube) – 120kg

Length (Excluding X-Ray Tube) – 1770mm (Plus Recovery Ring 246mm)

Optimum Tube Current – 2-3 milliamps

Focal Spot Size – 1.5 x 5mm

Power Source – Sealed Lead Acid Batteries (120v)

Battery Capacity – 24 Amp Hours

Motor Rating – 185w Continuous (quarter HP)

Travel Speed – Up to 22 metres per minute

Wheels – Contoured High Traction Rubber

Braking – Dynamic

Mean Positioning Accuracy (15° slope) – Plus or Minus 5mm

Maximum Angle of Climb (Optimum Conditions) – 30%

Temperature Range – 20° to +70° C

NEW FEATURES

REMOTE HANDSET: MULTI LANGUAGE TOUCH SCREEN

JME’s unique Handset allows external control and monitoring of the crawler whilst operating in the pipe, providing real time data on the crawler’s activity. It allows the operator to enable/disable all features of the Crawler and X-Ray generator prior to operation, avoiding a lengthy, complex analogue configuration.

CUSTOMISABLE ‘ANTI RUNAWAY’

‘Anti Runaway’ is a system which puts the crawler into reverse if it does not receive a signal from the Magnetope or Handset within a specified time period.

INTEGRATED RADIO RECOVERY

In the event of a malfunction within the pipe, the crawler’s internal logic can be overridden by the handset to reverse the crawler out of the pipe.

AMAX – AUTO MOVE AFTER X-RAY

When AMAX is enabled, the crawler will locate under the Magnetope and be signalled to start the X-Ray. Once the exposure is complete the crawler will automatically drive to the next weld, increasing site efficiency.

END OF PIPE SENSOR KIT / WATER DETECTION SENSOR KIT

End of pipe and water detection sensors are fitted to the front and rear of the crawler. End of pipe sensors detect the Crawler’s proximity to the pipe entrance and stop the system automatically, preventing accidental damage to the equipment. Water detection sensors stop the crawler if water is detected within the pipe. A handset message is displayed in both instances to alert the user.

SIMPLIFIED AND IMPROVED WHEEL/AXLE CHANGE

The revised axle change system allows for easier set-up in the field. A stationery center shaft combined with an axle extension provides the user with a swift set-up of the system for a variety of pipe sizes.

SINGLE MAGNETIC DETECTOR BOX

JME’s new crawler system incorporates a single Detector Box, covering the full spectrum of wall thicknesses up to 40mm. Removing the need to change the Detector Box as the wall thickness increases.

RANGE OF GAMMA PROJECTORS

Easy/simple crawler conversion from X-Ray generator to Gamma projector. Gamma actuators are compliant with all manufacturers safety mechanisms.

Product Picture