Phoenix ISL – Nozzle Scan

NozzleScan is a versatile manual scanning solution developed for the inspection of nozzle welds in both set-through and set-on configurations.

Available in both two-axis and three-axis instrument configurations and adaptable to cover a wide range of 90 degree nozzle sizes, from 3” upwards, on ferritic and austenitic materials.

Attaching to the branch component, the innovative modular design of NozzleScan offers a variety of configurations to encode circumferential and weld offset positions as the scanner travels around the nozzle.

NozzleScan features an overhead gimballed probe holder which allows the operator to hold the transducer conventionally for a more tactile inspection. Probe skew orientation is changeable (a critical requirement for inspecting many nozzles) and can be free-running or accurately adjustable, with the additional option of being encoded as a third axis, if required.

Attaching NozzleScan to the branch pipe can be achieved with either magnetic wheels for a wide range of ferritic pipe sizes, or with fixed size clamping rings for supreme accuracy on any material. Developed to satisfy demand for a solution, NozzleScan offers exceptional versatility to meet the inspection needs of industry.

Benefits :

• Transducer skew axis can be adjusted, encoded and locked.

• Two-axis and three-axis instrument configurations available.

• Modules for both set-through and set-on nozzle configurations.

• Options for mounting to ferritic and non-ferritic parent material.

• Adaptable to a wide range of 90 degree nozzle sizes, from 3” upwards.

• Encoders incorporated for semi-automated inspection data recording.

Specifications:

• Magnetic wheel mounting module for ferritic nozzles, clamping ring mounting module for non-ferritic.

• Adjustable probe skew axis, free-running or by screw adjustment.

• Probe skew axis optionally encoded for inspection with suitable three-axis instrumentation.

• Obstruction free probe mounting allowing the operator to hold the probe like a conventional inspection.

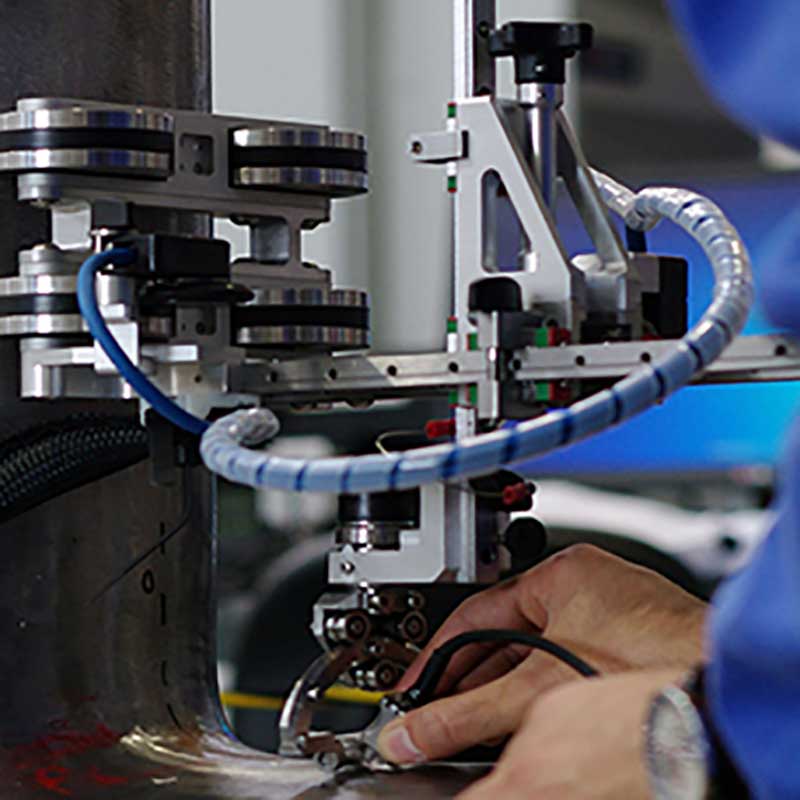

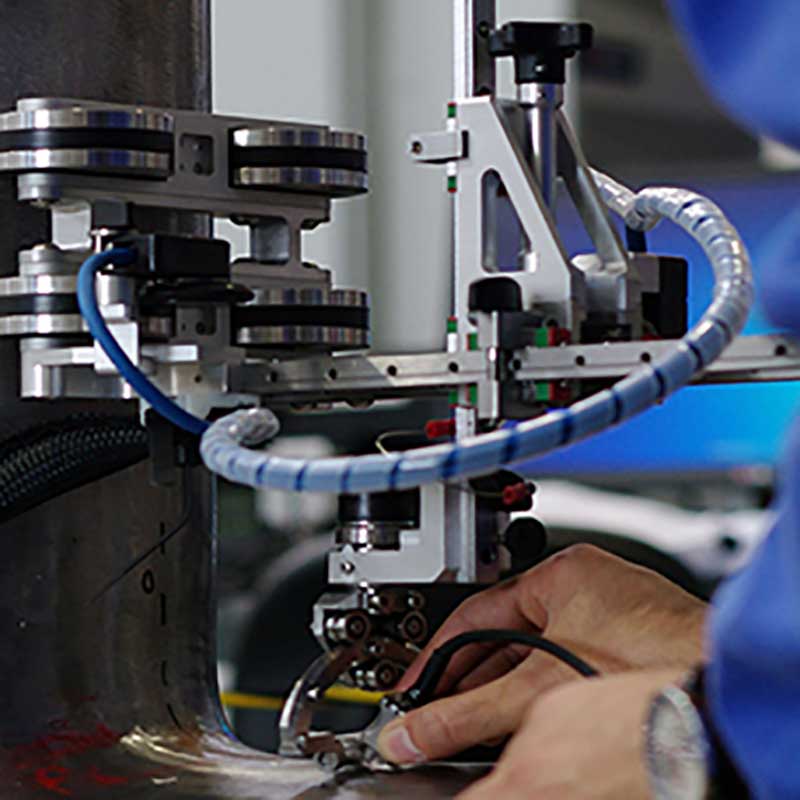

Product Picture