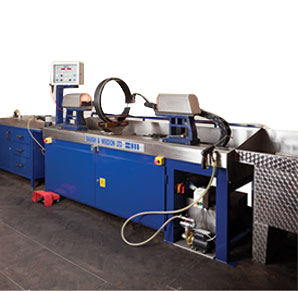

Designed for testing medium to large components, the MAGAZON EBU series of MPI benches is able to provide substantial magnetising currents where needed. The series comprises various bench sizes, a wide range of magnetising modes and current waveforms, and a variety of accessories and ancillary equipment.

Construction is based on a heavy duty framework fitted with a stainless steel drain tank. The power pack may be integral to the bench, or a separate unit. Pneumatic clamping at the headstock is foot operated, while the tailstock is manually positioned then clamped in place. Both head and tailstocks are equipped with test piece supports and easily replaceable copper mesh contact pads.

The power packs are supplied with nominally 3000A or 5000A RMS outputs as standard, although alternative outputs are available subject to technical appraisal. The provision for HWDC, or FWDC waveforms, either single or three phase, can also be accommodated. The power packs are fitted with thyristor control as standard. However, should a sinusoidal output be required, the option of variable transformer control is available.

All MAGAZON EBU series benches control the current using the CPS method (Current Pre-Selection). This allows the operator to select a given current and the bench will automatically achieve this value during the magnetising shot.

A built-in memory can store up to 99 sets of data, including test parameters for each component. This is useful where test batches are small and frequent changes are needed.

Multi-directional magnetising, or Swinging Field, allows two magnetising circuits to operate simultaneously, eliminating the need for multiple shots. Defects in any orientation can be highlighted, with only one viewing operation needed.

Automatic Sequencing provides a degree of automation which can be selected depending on the application. The sequence controls the clamping, inking, magnetising and unclamping automatically.

MAG-Link provides control of the bench via a PC. Techniques are written on the PC and when a job is performed, all of the bench settings are set up according to the technique. Full password protection is employed along with printed reports for full traceability.

Product Picture